|

An integrated system for fuel saving and top-level control of a ship's

performance. The system is operated from the central unit placed on the

bridge. The required values on speed, arrival times, and complete route plans

are input from the keyboard by the operator, normally the ship's first

officer or captain. The main engines (10-40.000 horsepower) and propellors

are then automatically adjusted to reach and maintain the required speed at

the lowest fuel consumption.

Fuel

saving is typically 5-10%, corresponding to about 1 cubic meter of heavy fuel

oil per day. The saving is achieved by two functions:

|

|

Pitch optimization

The pitch angle of the blades on a

controllable propeller acts as a kind of gear box and effects the ship's

speed together with the main engine's revolutions (rpm). The optimal combination

of pitch/rpm depends on a number of external conditions and therefore must

be subjected to dynamic optimization in order to be optimal.

|

|

|

Route

planning

The fuel consumption for a ship depends

not only on speed but also on water depth and weather conditions. The

optimal speed distribution along the route can be computed in advance if

weather forecast is available.

|

I started to develop the SeaPacer in 1985 and have been working on development,

manufacturing, and installation in the one-man company Seapacer AB ever since. Around 20 systems are now running on

ferries operated by Stena Line, TT Line, Silja Line, EstLine and others.

The product had been marketed by KaMeWa AB

and Stena Line until 1994, when I regained the marketing rights. However, the

obvious limitations of a one-man company have resulted in a rather passive

marketing the last years. The most recent installation was on MS Gotland

(Gotlandsbolagen) in the beginning of 1997.

More information about the SeaPacer system is provided in the following pages:

Route

Planning Route

Planning

Diagrams

Available in the System Diagrams

Available in the System

Inputs and

Outputs Inputs and

Outputs

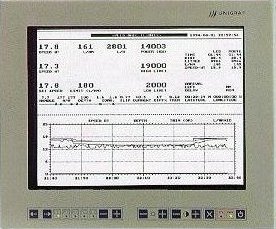

SeaPacer Main

Screen SeaPacer Main

Screen

|